Foil Finishing Mills

The consumption of foil has increased tremendously in the last decade and it continues to grow. Increase in demand in aluminium foil is a typical characteristic of developing economies. These days applications of foil are wide and varied making it ubiquitous.

The increase in demand has in turn led to evolution of foil finishing mills. Modern mills have wider width and higher speeds with increasing automation, reducing the dependency on labour capital. Low wastage, operator convenience and production planning are essential features of today’s foil mill.

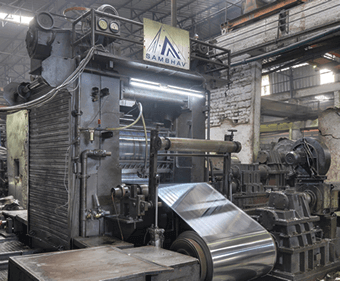

Sambhav machinery manufactures high productivity foil mills with a very low capital cost without compromising on the quality.

Basic Specifications

| Width (max) | 2000mm |

| Thickness | 0.15 mm – 0.006 mm * 2 |

| Speed (max) | 1200 mt/min |

The demand for aluminium foil continues to grow, given such a marvellous product which it is.

Such growth should also be sustainable. This means continuous designing of efficient foil mills according to requirements of market in order to increase productivity while also being competitive.

However, quality is the defining factor in today’s foil market. Usage and application of foils are varied and this means that foil mills not only should produce excellent quality, but also the setup should be flexible and easily adaptable. Foil manufacturers should be able to cater to high volume generic markets as well as to the value added niche customers.

Sambhav also factors in the economics of aluminium rolling while designing its foil mills.

The rising costs of production has ensured that only the most efficient and competitive foil mills will be successful and one important aspect of this is wastage reduction.

Easy maintenance is also important for improving plant availability and for long term performance.

In short, today’s foil manufacturers require a sophisticated technology which produces high quality product at lower cost along with high plant availability and long term performance.

This is where Sambhav comes in, as we are dedicated solely to optimising the performance of aluminium rolling mills.

Preventive maintenance strategies minimizes unplanned downtime and in turn reducing costs and increasing productivity.

With a proven track record for conducting integrated rolling complex projects and supplying process equipment, we can also define supply and install auxiliary facilities including slitting, grinding, annealing and converting.

FFMs are our most esteemed and prized equipment. They are technically the most demanding as foils of thickness as low as 6 microns can be manufactured at high speeds. They require superior sophistication in all the parameters and ancillary equipments related to the mill. Sambhav Machinery is proud to commission its last foil mill project in a way that the first rolled coil was of marketable quality. This confidence helps the customers to cater to the market in little time with no scrap loss.

| Width | 600mm – 2000mm |

| Thickness | 900 microns – 6 microns * 2 |

| Speed | < 1000 mt/min |

| Thickness | 6 – 10mm |

| Weight | < 7 mt |

End Products

Household Foil, Capacitor Foil, Pharmaceutical Foil , Converter Foil, Container Foil, Lidding Foil